The Best Strategy To Use For Premier Aluminum Llc

Premier Aluminum Llc - Questions

Table of ContentsThe Only Guide for Premier Aluminum LlcThe Of Premier Aluminum LlcAbout Premier Aluminum Llc6 Simple Techniques For Premier Aluminum Llc

(https://www.pinterest.com/pin/1110489220619623802)Making use of low expense and unqualified vendors can create quality concerns, and lost time and money in the long run. To aid you through the procedure, below are some things to consider when choosing the best steel casting distributor.

As an example, a firm that only makes use of the investment spreading procedure will try to offer you on why that process is best for your application. What if using the sand casting process is best for you and your requirements? Rather, look for a supplier that supplies a variety of casting procedures so the very best choice for YOU is chosen

If working with a single source for every one of your spreading requires is very important to you, the provider needs to be varied in its capacities. When incorporated with other integrated abilities, this can assist simplify and press the supply base. When picking the right casting distributor, careful factor to consider should be offered to quality, service, and cost.

All About Premier Aluminum Llc

Customers significantly select spreading distributors that have machining capabilities. This can stay clear of problem if issues are uncovered throughout machining. If a 3rd party is machining, it may result in "finger-pointing" about that is at fault. Is it a spreading concern or a machining problem? If the casting distributor uncovers an issue throughout machining, the issue More Help is settled faster without any dispute over whose fault it is.

What do you require from your spreading provider? Are you looking for a person to just deliver a steel part to your front door or do you require a lot more?

Some factories are limited or specialized. Make sure the distributor can meet all your product or alloy requirements to remove the need for numerous vendors.

The Best Strategy To Use For Premier Aluminum Llc

Research the supplier's site. Speak with a sales representative or business associate. Ask a great deal of concerns. Visit their facility. Obtain an understanding of what they can do for you and if you can see on your own constructing a strong, shared connection with them.

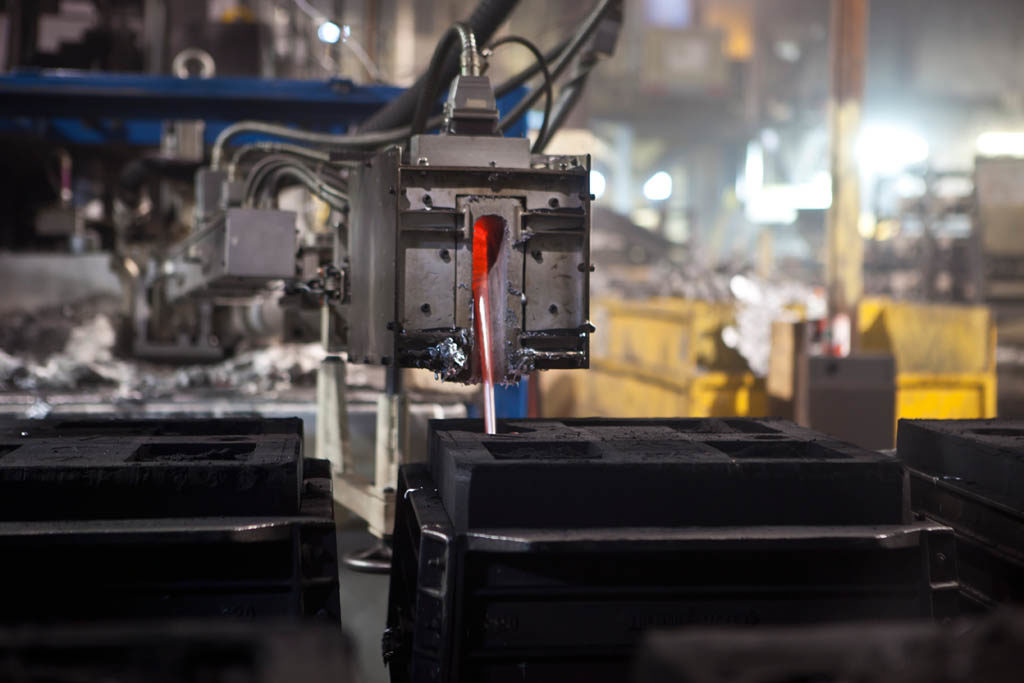

Aluminum is also light-weight and has excellent corrosion resistance, making it excellent for applications where weight and durability are very important factors. Additionally, light weight aluminum casting is a cost-effective approach of production, as it calls for less power and sources than various other approaches. Iron casting, on the other hand, includes putting molten iron into a mold and mildew to create a desired shape.

Some Known Details About Premier Aluminum Llc

Iron casting is likewise able to withstand heats, making it suitable for use in applications such as engine parts and industrial equipment. Nonetheless, iron spreading can be extra pricey than aluminum spreading due to the greater expense of raw materials and the power called for to thaw the iron. When deciding in between light weight aluminum casting and iron casting, it is essential to think about the certain requirements of the application.

In verdict, both light weight aluminum casting and iron spreading have their own unique advantages and drawbacks. There are three sub-processes that fall under the category of die spreading: gravity pass away spreading (or irreversible mold spreading), low-pressure die casting and high-pressure die casting. To obtain to the completed item, there are 3 key alloys utilized as die casting product to select from: zinc, light weight aluminum and magnesium.